Heating Capacity: 350 to 14,000KW (300,000 to 12,000,000KCAL)

Working Media: Heat Transfer Oil

Working Temperature: ≤350℃

Fuel: Natural Gas, #2 Light Oil , Heavy Oil

Brief Introduction

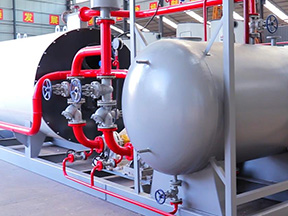

YY(Q)W series gas oil fired thermal oil boiler is packed and full automatic thermal oil boiler, adopts three-pass structure, full corrugated coil. The heat carrier is heat conduction oil, rated working pressure 1.1MPa, working temperature ≤350℃. After boiler arriving at users’ site, only need to consider to fill the heat conduction oil, connect fuel (gas or oil) and electricity source.

Product Application

Petrochemical, Textile Printing/ Dyeing, Plastic Industry, Rubber Plant, Food Processing, Wood Processing, Asphalt Heating, Carton Production, Vegetable Dehydration, Baking Varnish, Casting Sand Mold Drying, etc.

The Features

High Quality Control: In manufacturing processes, we has adopting steel strength test, automatic steel cutting/ plate rolling/ welding, 100% x-ray welding check, magnetic particle check c-scan ultrasonography check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency test,etc, to make sure all finished products is qualified.

Durable Coil Heater: YY(Q)W series adopting high quality corrugated coil to carry the heat conduction oil, increase the heat transfer area, reasonable gap between coil tubes to fit the hot expansion and cold contraction . Average coil tubes' working life more than 17years.

Automatic Safe Operation: Full automatic PLC ON/OFF controller, free settable thermal operation temperature and working time, automatic temperature control, automatic over-pressure/ over temperature interlock chain stop protection, visible system's working states (burner's states, system working pressure/ oil temperature) on screen etc.

Item/ Model | YY(Q)W 350 | YY(Q) W500 | YY(Q) W700 | YY(Q)W 1000 | YY(Q)W 1200 | YY(Q)W 1400 | YY(Q)W 1800 | YY(Q)W 2100 | YY(Q)W 2400 | ||

| Heating Power | KW | 350 | 500 | 700 | 1000 | 1200 | 1400 | 1800 | 2100 | 2400 | |

| Kcal/H | 300000 | 420000 | 600000 | 850000 | 1000000 | 1200000 | 1500000 | 1800000 | 2000000 | ||

| Woring Temperature | ℃ | ≤350 | |||||||||

| Available Fuels | / | Gas (natural gas, lpg, biogas), Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) | |||||||||

| Combustion Method | / | Pressurized combustion in chamber | |||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working temperature | |||||||||

| Item/ Model | YY(Q) W2900 | YY(Q)W 3500 | YY(Q)W 4700 | YY(Q)W 6000 | YY(Q)W 7000 | YY(Q)W 10000 | YY(Q)W 12000 | YY(Q)W 14000 | ||

| Heating Power | KW | 2900 | 3500 | 4700 | 6000 | 7000 | 10000 | 12000 | 14000 | |

| Kcal/H | 2500000 | 3000000 | 4000000 | 5100000 | 6000000 | 8500000 | 10000000 | 12000000 | ||

| Woring Temperature | ℃ | ≤350 | ||||||||

| Avalliable Fuels | / | Gas (natural gas, lpg, biogas), Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) | ||||||||

| Combustion Method | / | Pressurized combustion in chamber | ||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working temperature | ||||||||

Burner

Oil Circulation Pump

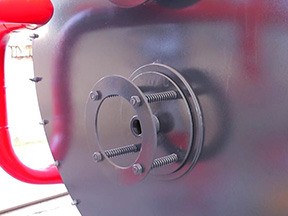

Furnace Explosion-Proof Door

Thermometer

Pressure Gauge

Expansion Tank

Storage Tank

Oil Gas Separation Filter