Steam Capacity: 500 to 20,000 KG/H

Boiler Power: 32 to 1,278 HP

Pressure: ≤16 Bar

Fuel: Natural Gas, #2 Light Oil, Heavy Oil

Brief Introduction

WNS series horizontal internal combustion boiler is a boiler shell type 3 passes wetback oil/gas fired boiler. After fuel is being atomized by burner, flame is full of the wave furnace and transfer heat via furnace wall, this is 1st pass; the high temperature smoke is collected in reversal chamber and then enters 2nd pass which is grooved tubes bundle area; after heat convection, air temperature gradually falls and goes to front smoke box and turn to 3rd pass, which is smooth tubes bundle area, and then enters chimney passing back smoke box and exhausted to the atmosphere.

Product Application

Textile, Garment, Food & Beverage, Chemical Industry, Cement Curing, Disinfection,etc.

The Features

Special Structure & High Efficiency: Adopting corrugated furnace, threaded firetubes, 3 fire-passes structure, full wetback deisgn, markedly increased boiler's heating area and heat transfer efficiency. It is equipped with renowned brand burners (BALTUR, RIELLO, HOFAMAT, or ECOFLAM), also finned tube type economizer can ensure boiler's thermal efficiency up to 95%.

High Quliaty Control: In the manufacturing processes, TGBOILER® adopts steel strength test, autmatic steel cutting/ plate rolling/ welding, 100% x-ray checking, magnetic particle check, C-scan ultrasonography Ultrasound check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency test,etc, to make sure all finished products is qualified. Automatic Safe Operation: WNS series boiler is equipped automatic burner ignition, automatic water-level control, automatic pressure control, automatic interlock chain stop protection, free settable working pressure, free settable ON/OFF time, visible system’s working states on screen.

Easy Maintenance: WNS series boiler uses full water back tube-sheets instead of traditional dry back tube-sheet, can avoid the dry fire broken, reduce the range of steel cooling contraction and hotting expansion. Also, we adopting openable smoke-boxes, users can replace the broken fire-tubes conveniently.

| Item/Model | WNS0.5 | WNS0.7 | WNS1 | WNS1.5 | WNS2 | WNS3 | WNS4 | WNS5 | WNS6 | ||

| Capacity | kg of steam per hour | 500 | 700 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | |

| HP | 32 | 44 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | ||

| Pressure | Bar | ≤10 | ≤10 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤16 | |

| Steam Temperature | ℃ | ≤184 | ≤184 | ≤194 | ≤194 | ≤194 | ≤194 | ≤194 | ≤194 | ≤204 | |

| Available Fuels | / | Gas (natural gas, lpg, biogas) Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) | |||||||||

| Thermal Efficiency | % | >92 | |||||||||

| Combustion Method | / | Pressurized combustion in chamber | |||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working pressure | |||||||||

| Dimension | L | mm | 2950 | 3050 | 3250 | 3450 | 3880 | 4260 | 4800 | 4950 | 5490 |

| W | mm | 1550 | 1600 | 1770 | 1910 | 1900 | 2130 | 2200 | 2250 | 2250 | |

| H | mm | 1730 | 1790 | 2070 | 2200 | 2180 | 2450 | 2500 | 2500 | 2700 | |

| Weight | kg | 3700 | 4100 | 4800 | 5900 | 6800 | 9100 | 12500 | 14800 | 16200 | |

| Item/Model | WNS8 | WNS10 | WNS15 | WNS20 | SZS20 | SZS25 | SZS30 | SZS35 | ||

| Capacity | kg of steam per hour | 8000 | 10000 | 15000 | 20000 | 20000 | 25000 | 30000 | 35000 | |

| HP | 512 | 639 | 959 | 1278 | 1278 | 1598 | 1917 | 2236 | ||

| Pressure | Bar | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | |

| Steam Temperature | ℃ | ≤204 | ≤204 | ≤204 | ≤204 | ≤204 | ≤204 | ≤204 | ≤204 | |

| Avalliable Fuels | / | Gas (natural gas, lpg, biogas) Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) | ||||||||

| Thermal Efficiency | % | >92 | ||||||||

| Combustion Method | / | Pressurized combustion in chamber | ||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working pressure | ||||||||

| Dimension | L | mm | 6670 | 6980 | 7500 | 8200 | 9350 | 11000 | 10450 | 12000 |

| W | mm | 2600 | 2600 | 3200 | 3400 | 3600 | 3650 | 3890 | 4000 | |

| H | mm | 3100 | 3300 | 3560 | 4100 | 3650 | 3950 | 4210 | 4210 | |

| Weight | kg | 19600 | 27400 | 38000 | 47000 | 39000 | 44000 | 48000 | 52000 | |

Burner

Feedwater Pump

Economizer

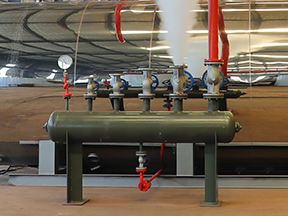

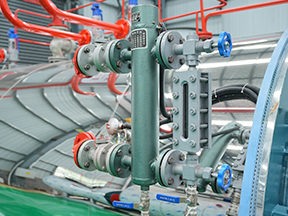

Steam Manifold

Pressure Relief Valves

Water Level Sensor

PLC Control System

Pressure Control